- info@pfila.in

- Nelamangala, Bengaluru, Karnataka 562123

At Parshvanath Filaments, we prioritize customer delight, quality, innovation, integrity, teamwork, and sustainability in all that we do.

The firm manufactures PP Multifilament and the firm is 100% into manufacturing activity.

The Company procures raw materials of Plastic Graneals from suppliers like Sowbagya polymers (Reliance Agent), Bangalore and Pulcra chemicals, Thane etc.

The plastic granules (Raw Material) is used to manufacture PP Multifilament Yarn (Finished Product).

The entire production from procuring raw material to the finished product will take 25-30 days and the firm holds the finished product for another 30 days so the total stock-holding period will be around 60 days.

Due to the long-standing presence of promoters in the business and profitable operations in last few years, the customer base is increasing Y-O-Y along with TO.

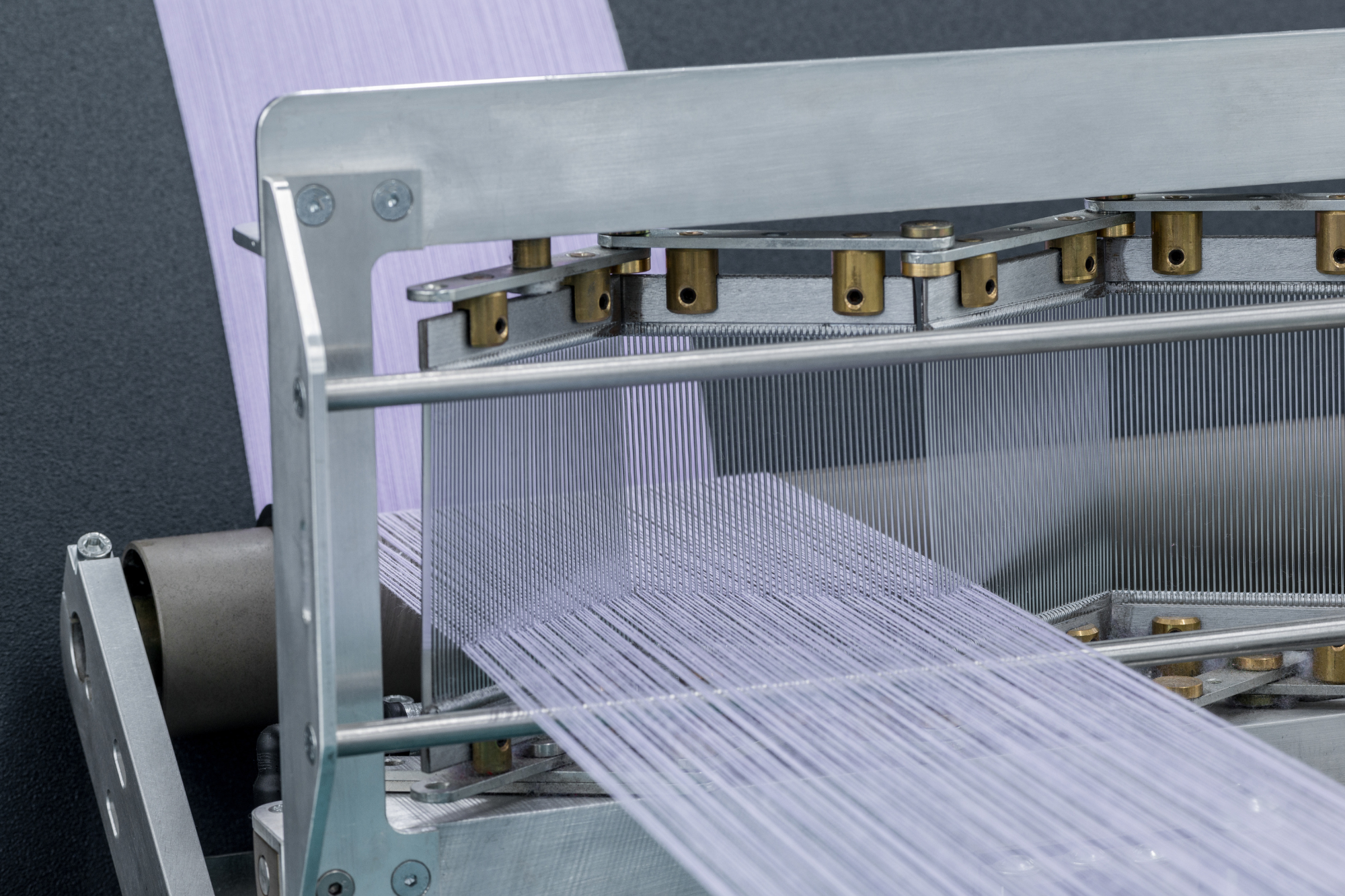

Extrusion

The process starts with melting the plastic granules and forcing the molten material through a spinneret, a metal plate with tiny holes. This creates continuous filaments.

Drawing

The filaments are then stretched to align the polymer chains, increasing their strength and orientation. This involves passing the filaments through a series of heated rollers at controlled speeds.

Winding

After drawing, the filaments are wound onto bobbins, creating a compact and uniform package of multifilament yarn that is ready for further processing or use in various applications.

The production as of now is 250 tonnes/month against a production capacity of 300 tonnes/month and the factory runs 24*7(24 hours, 7 days) and the employees will be working shifts-wise.

Incorporating cutting-edge technology and fostering a culture of innovation, we continuously push boundaries, optimizing production processes, and developing advanced materials to stay at the forefront of the industry.

We boast a skilled and well-trained workforce of 110 employees whose expertise and meticulous attention to detail guarantee the highest quality standards